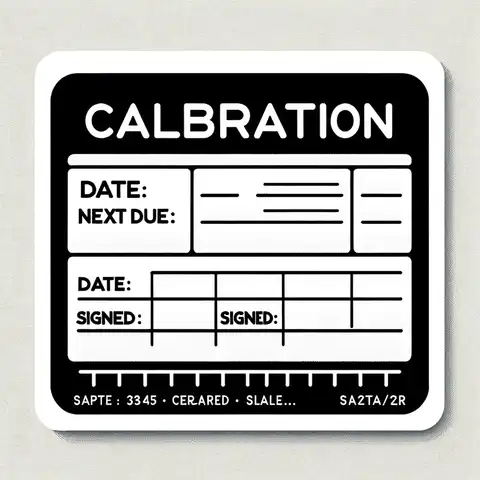

Calibration label templates are super helpful in places like factories, labs, and anywhere people use special tools and machines.

They have a big job: they tell us when a tool or machine was last checked and when it needs to be checked again. It’s like having a mini calendar on each piece of equipment! This keeps everything running smoothly and makes sure we follow rules that keep everyone safe.

So, in this article, we’re going to dive into the world of calibration labels. We’ll look at different types, what information they carry, and how they help us in our work. It’s going to be fun and super useful, so let’s get started!

Calibration Label Template

Calibration labels are like special stickers we put on tools and machines. They tell us important stuff, like when a tool was last checked to see if it’s working right and when it needs to be checked again. This helps to make sure our tools and machines are safe and doing their job well.

Different Kinds of Calibration Labels

- Calibration Due Labels: They’re like reminders stuck on tools, telling us when the next check-up is needed. They help make sure we don’t forget to check if everything’s working right.

- Asset Tags: These are like name tags for tools and equipment. They help us know which tool is which and where it belongs.

- CNR (Calibration Not Required) Labels: Some tools don’t need regular check-ups. These labels tell us that, so we know those tools are okay as they are.

Special Types of Labels

- Tamper-evident Labels: They’re like security guards. If someone tries to mess with the label, we’ll know because these labels show signs of tampering.

- Color-coded Labels: These labels use different colors to tell us things quickly. Like, a red label might mean it’s urgent, or blue could show which department the tool belongs to.

- Self-laminating Labels: They are super tough! They have a protective layer that keeps the important info safe from water, dirt, or scratches.

Each type of label has its superpower in keeping tools and equipment in check!

Requirements for Calibration Labels

Calibration labels have to follow certain rules to be really useful. They need to:

- It is easy to read and understand.

- Stay on the equipment well, even in tough places like where it’s really hot or wet.

- Include important info like who checked the tool, when, and what they found.

This helps everyone know that the tools and machines are ready to use and safe.

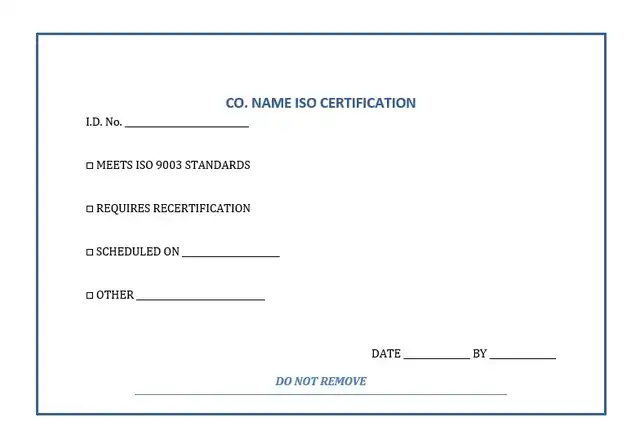

Label Templates and Customization

Making calibration labels is easy! You can start with pre-made templates, like a recipe for stickers. These templates have everything laid out, so you need to fill in your details.

But guess what? You can also change these templates to fit what you need.

The outline is already there, and you just need to add your colors and details.

- Online Resources: Look for websites that offer label templates. They often have a bunch you can choose from.

- Software Packages: Some calibration software comes with built-in label templates. It’s like a bonus with the software!

Customizing Label Templates

Now, here’s where you can get creative:

- Add Your Info: You can type in things like the tool’s name when it needs to be checked next, and who checked it last.

- Change the Design: You may want to add a logo or change the label’s size.

- Make It Fun: Play with colors and fonts to make your labels stand out, but remember, they still need to be easy to read.

- Save Your Designs: Once you’ve made a label you like, you can save it.

Customizing labels is like making a mini-poster for each tool. It’s fun and helps keep everything organized!

Label Fields and Information

Labels can have lots of information. Here are some things they might include:

- For Asset Labels: They might show a tool’s name or a special code to identify it.

- Due Cal Labels: These tell us when the next check is due for a tool.

- Maintenance Labels: They give information about when a tool was last fixed.

- System Labels: These are for bigger equipment and might include details about the whole system.

Label Material and Durability

When it comes to calibration labels, picking the right material is super important. Different environments need different kinds of labels. Here’s what to think about:

- Toughness Against Weather: If your tool is outside a lot, your label should be able to handle sun, rain, or snow.

- Resistance to Chemicals: In places like labs, labels might get splashed with chemicals. They need to be strong enough not to smudge or fade away.

- Handling Heat and Cold: Some labels have to stay on tools in really hot places like near engines or super cold freezers. They need special materials that won’t melt or crack.

- Waterproof Qualities: If your tool gets wet, the label should be like a raincoat – keeping all the info safe and dry.

- Stickiness: The label needs the right kind of glue. It should stick well but also come off when you need to change it without leaving a sticky mess.

- Visibility and Readability: The material should be clear to read. If it’s too shiny or gets scratched easily, it might be hard to see the info.

How Calibration Labels Work with Systems and Software

Calibration labels and tracking systems are like a superhero team. Here’s how it works:

- Scanning and Reading Labels: Modern systems can scan the labels on tools and machines. This is like a quick check-in, telling the system who’s there and when they were last checked.

- Updating Records Automatically: When a label is scanned, the system updates records. It’s like having an automatic diary that keeps track of all the check-ups and work done on each tool.

- Alerts and Reminders: The system can use the label info to remind you when it’s time for the next check-up.

- Data Accuracy: Since everything is scanned and automated, there are fewer mistakes.

- Time-Saving: With labels and software talking to each other, people don’t have to spend as much time writing down or typing up info. This means more time to do other important stuff.

Practical Tips for Effective Labeling

- Choosing the Right Label Type: Some labels need to stick around forever (permanent), and some can come off when we need to update info (removable). Think about your tool – will it need new labels often, or just one that stays for a long time?

- Adhesive Strength and Environment: Make sure your label sticks well! If it’s going to be in a hot, cold, or wet place, you need a super strong sticker.

- Label Color and Material: Colors can help a lot. For example, different colors can show which month a tool was checked. Also, choose a material that can handle where the tool will be – like waterproof labels for wet places.

Why Calibration Labels Are Important

Here’s why they’re so important:

- Accuracy and Safety: They make sure tools work right so nobody gets hurt.

- Compliance with Standards: They help us do things the right way, just like following rules in a game.

- Maintenance Tracking: These labels keep a record of when the equipment was last calibrated

- Efficiency and Reliability: With these labels, people know their tools are good to go!

- Cost-Effective: Fixing things before they break can save money. It’s like finding a small hole in a tire before it goes flat!

- User Confidence: When tools have these labels, we know we can trust them to work well.

Conclusion

Spending some time to make the perfect labels is really important. It’s like creating a special map for each tool so we always know where it’s been and where it’s going.

So, let’s give a big cheer for these tiny but mighty heroes that help keep everything in tip-top shape!